Troubles? No way! Strategies leading to accurate impressions

Accurate impressions for precisely fitting restorations: Effective measures shared by an experienced trainer help minimize risks in the impression procedure.

The process of taking precision impressions is riddled with potential errors. Errors in the process can compromise the quality of the impression, which in turn has a decisive impact on the fit of the final restoration. Therefore, it is important to know how to avoid them. Experience from more than 100 training courses in dental offices shows that everyone taking impressions tends to make the same mistakes and that these mistakes are usually easily avoidable. This article summarizes the most frequent errors that occur in the procedure and reveals proven strategies for success.

Potential sources of error

There are essentially four different areas where missteps might occur that could have a negative impact on the quality of the final impression:

- Practice management

Errors that fall in the category of practice management include those caused by inconsistencies in the materials and workflows and an unclear allocation of tasks in the team. Organizational issues, like long distances between the mixing device and the chair, and suboptimal storage conditions are also factors that might affect the impression quality. - Tray and material selection

An inaccurate impression may be the result of a wrong tray size or a lack of rigidity. Limited suitability of the selected material for the preferred technique, inappropriate setting times or lack of compatibility between tray and wash material may also lead to inaccuracies. - Impression procedure

Critical points in the procedure include mixing tip attachment, tray filling, and tray insertion and removal from the mouth. - Follow-up measures

Finally, immediate disinfection, storage in moist conditions or unsteady temperatures, and high intensity UV daylight exposure during transport to the laboratory may have a negative effect on the quality of the impression.

Practice management: How to standardize

One of the most effective measures contributing decisively to a high quality and accuracy of the precision impression is standardization of the whole impression taking procedure. Within the practice team, tasks have to be allocated clearly, so that every single person knows exactly what to do. The ideal situation would be that every dental practitioner in an office uses the same materials and adheres to the same protocols, so that one dental assistant can substitute for another without errors stemming from process missteps.

When establishing standardized procedures, the team should not only define when to use which kind of materials and devices, but also focus on:

- Finding the right place for the equipment. An automatic mixing unit, for example, should always be positioned close to the chair to facilitate ideal time management even when working with quick-setting impression materials.

- Assuring a suitable storage area: Ideal temperatures may differ from material to material. VPS is usually more sensitive to higher than recommended temperatures than polyether. In both cases, a too-high storage temperature will shorten the material’s working time. If your storage area swings warm, the use of a less quick-setting material variant may be advisable. If storage temperatures are below the recommended minimum, mixing problems may occur. If this describes your storage situation, the material should be stored at room temperature (not on a heater!) for one day before it may be used again. When selecting a suitable storage location, the impact of the surrounding equipment (e.g. proximity to a refrigerator or sterilizer producing heat) should be taken into account.

Material and tray selection: Recommendations

For accurate full arch impressions, the use of a rigid, non-perforated metal or plastic tray is highly recommended. Rigidity is important as it avoids inaccuracies caused by deformation. The tray size should be checked intraorally to ensure that uniform space (2 to 3 mm) is available around the teeth equator line (this takes undercuts into account). If a tray is too small, the risk is high that the impression will have defects and a limited reproduction of details.

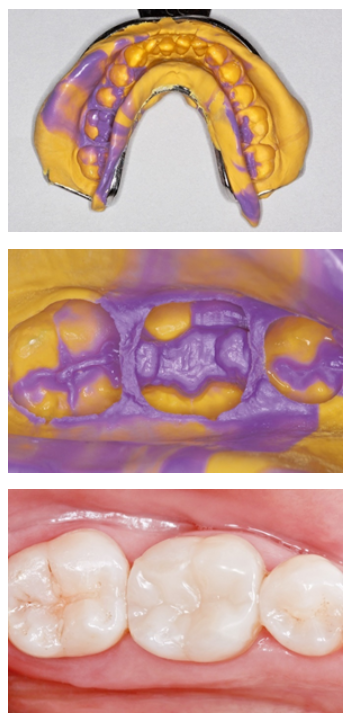

Impression taken with a metal tray that is too small and an

exceeded working time, which is responsible for a poor

bond between the materials. Long flow defects are visible

in the palatal area.

When selecting the impression material, different factors such as the compatibility between the material and the preferred technique need to be taken into account. Polyether is preferable for the monophase and 1-step techniques, while VPS is particularly well-suited for the 2-step technique and also works well with the 1-step technique. When choosing a VPS impression material, the user should select a product with good flow properties, plus hydrophilicity in the unset stage, which is not offered by every available product. The setting times should be selected based on the number of prepared teeth or implants to be captured.

Impressioning procedure: Tips and tricks

If you use an automatic mixing device, the impression taking procedure usually begins with automatic mixing and tray filling. Care needs to be taken with regard to:

- Correct insertion of the cartridge into the device

- Proper attachment of the mixing tip before each use: if the tips are not seated tightly on the outlet openings, inhomogeneous mixing results, a long setting time or a high amount of material waste may be the result.

- Verification of a homogeneous mix quality: before starting to fill the tray or elastomeric syringe, a small amount of material should be dispensed onto a mixing pad or paper towel to enable you to visually check the mix quality. This is also necessary for materials from a hand dispenser.

- Dispensing for a void-free mixture: the end of the mixing tip should always be immersed in the dispensed material during tray filling.

- The right timing: tray filling should be completed as soon as the dentist is done syringing the wash material (1-step technique), which is particularly important for quick-setting materials like 3M™ Impregum™ Super Quick Polyether Impression Material. This is usually possible when syringing and filling the tray start at the same time.

Poor bond between tray and wash material, presumably

caused by an exceeded working time.

Another important factor is the proper insertion of the loaded tray into the mouth. It needs to be moved slowly parallel to the long axis of the teeth before seating it straight up (maxilla) or straight down (mandible). Once the tray is in its final position with the handle aligned with the patient’s midline (assuming a full arch tray is being used), any movement needs to be avoided until the setting reaction is completed. Proper seating prevents distortions. It is useful to stabilize the tray in the premolar area with the fingers.

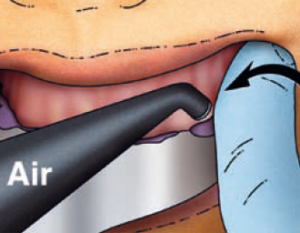

Some impression materials from 3M offer specific features that ensure a quick transition from the set to the unset state (such as self-warming of 3M™ Imprint™ 4 VPS Impression Material and snap setting of 3M™ Impregum™ Polyether Impression Material, which means less time for unintended movements. With regard to tray removal, releasing the vacuum with a finger aided by a stream of air is essential.

Measures facilitating removal of the impression from the mouth.

Follow-up measures: Doing it right

Any impression removed from the mouth should be rinsed with water, dried with air and disinfected with a mild solution before any other action is taken. Both, VPS and polyether impressions need to be stored in a cool, dry and dark place, and they should be shipped to the dental laboratory wrapped in dry paper towel and placed in an open bag if still moist. The dry paper will draw any moisture from the surface, leading to an optimal condition for transportation. Variations in temperature should be avoided.

Image: Precise impressions will lead to perfectly fitting restorations! (Images courtesy of Dr. Gunnar Reich)

Conclusion

The quality and accuracy of an impression has a huge impact on the quality and fit of the final restoration. Despite the complexity of the procedure, it is possible to ensure consistently accurate results with the effective measures described above. The key to success is standardization of the complete procedure, from tray filling to shipping of the final impression.

More information on how to avoid potential errors in the impressioning procedure is available here.